How Are Vinyl Records Made? How A Vinyl Record Is Made

If you are anything like us, sometimes when you get deep enough into a hobby you begin to think about things like the history, how it is made, or even who thought of it. At Vinyl Bro we hope to be able to answer all of those questions for you when it comes to vinyl records. Today we seek to at least fully answer one of these questions.

So, How Are Vinyl Records Made?

The process is a cool one that has not changed very much in the last 50 years. Most people may think it is a super hard or complicated process but it is pretty straight forward. To put it simply you record your track, make a master disc, and press your poly vinyl chloride pellet biscuit. Boom, now you have a record! We know though if you have landed here you are looking for much more detail, the way we usually break it down.

Step 1: Recording An Album

This is a whole process in its own right. We could probably write an entire post on the cost and process to begin recording your album but since this post is about how vinyl records are made we will summarize it as best as we can. Generally speaking, you would find a studio in your budget and ask them about their specific process however it should look a lot like the process outlined below.

There are several phases to the recording of just one song. You need to record your backtrack which is usually your general beat and chord progression. From there you will move into rhythm, harmony, and melody. Once you have recorded everything you move on to editing and mixing your album. Congratulations you have now recorded your album! Let’s move on to production.

Step 2: Creating A Lacquer Master Disc

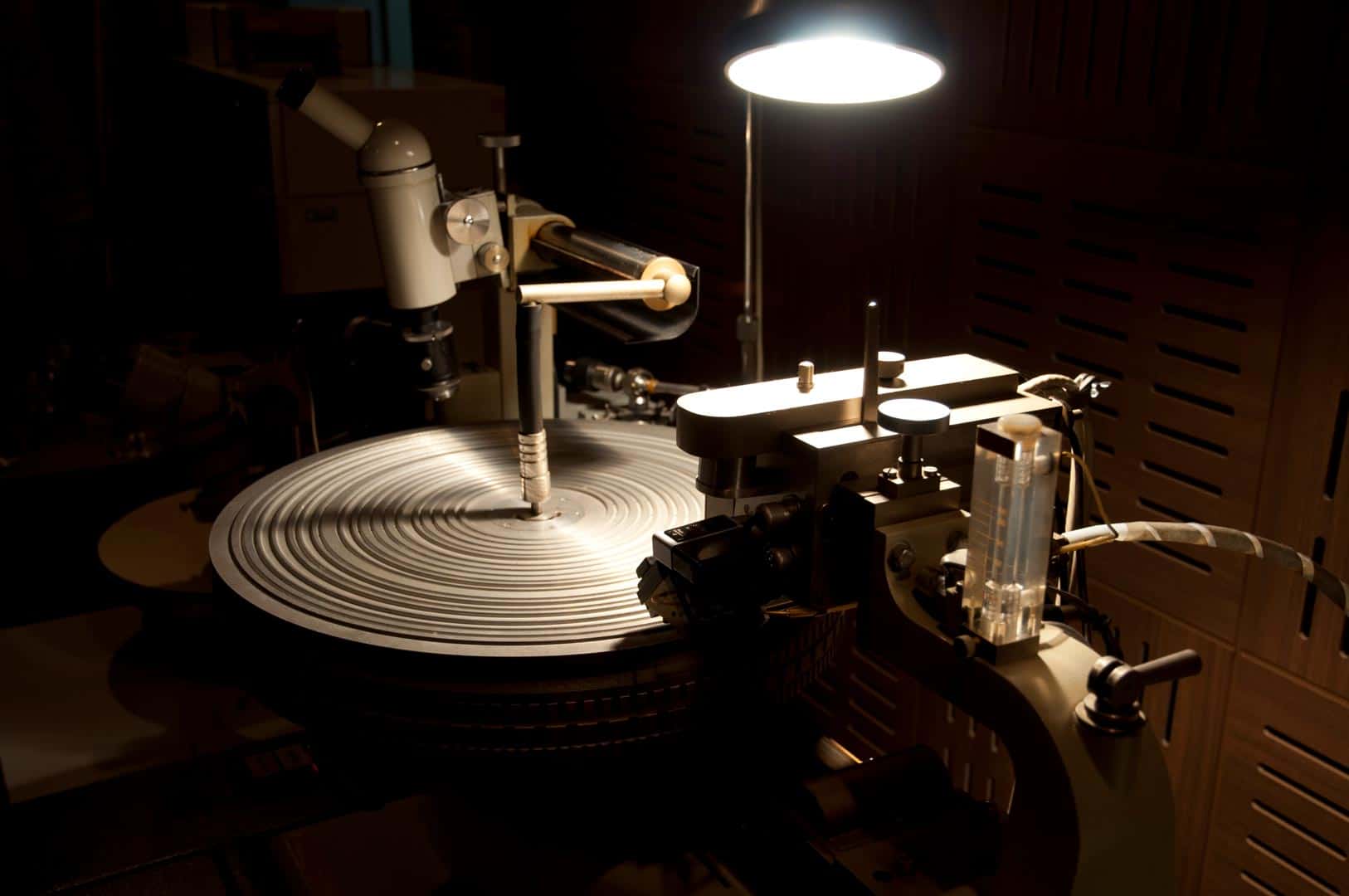

A vinyl master is the first cut and most important part of the vinyl record creation process. In this process, the artist works with their sound or mastering engineer to create and master a recording for vinyl. Once this mastering is completed the vinyl mastering begins. This is where a master lacquer will be cut using a cutting lathe.

Those master lacquers are what are sent over to the pressing plant for manufacturing. When cutting master they use 1 lacquer per side. So if you have a double 12 inch LP they used four 14 inch lacquers to create the full album. They use 14 inches for a 12 inch LP because it allows the engineers room on the lacquer for safe handling.

After the master engineer and artist have agreed on the cut to use the album is moved on to plating. If you are more curious about this master lacquer or master disk process this video does a great job at breaking it down.

Step 3: Plating A Vinyl Record

Electroplating, also known as “plating”, is the next step of the process a vinyl record takes in production. Plating the lacquer into a metal disk called the “Father” which is usually plated from nickel. The “Father” is usually used to create a subset of copies referred to as the “Mother” copies made from other metals such as copper.

The “Father” itself can be used to create a very small run of records which is why they usually created “Mothers” for the stamping. During this part of the process, the artist will have to decide what method they want to use called steps. There is 1 step, 2 steps, and 3 steps. The more steps the more mothers can be produced and the more records can then be created.

Nickel Plating Disk

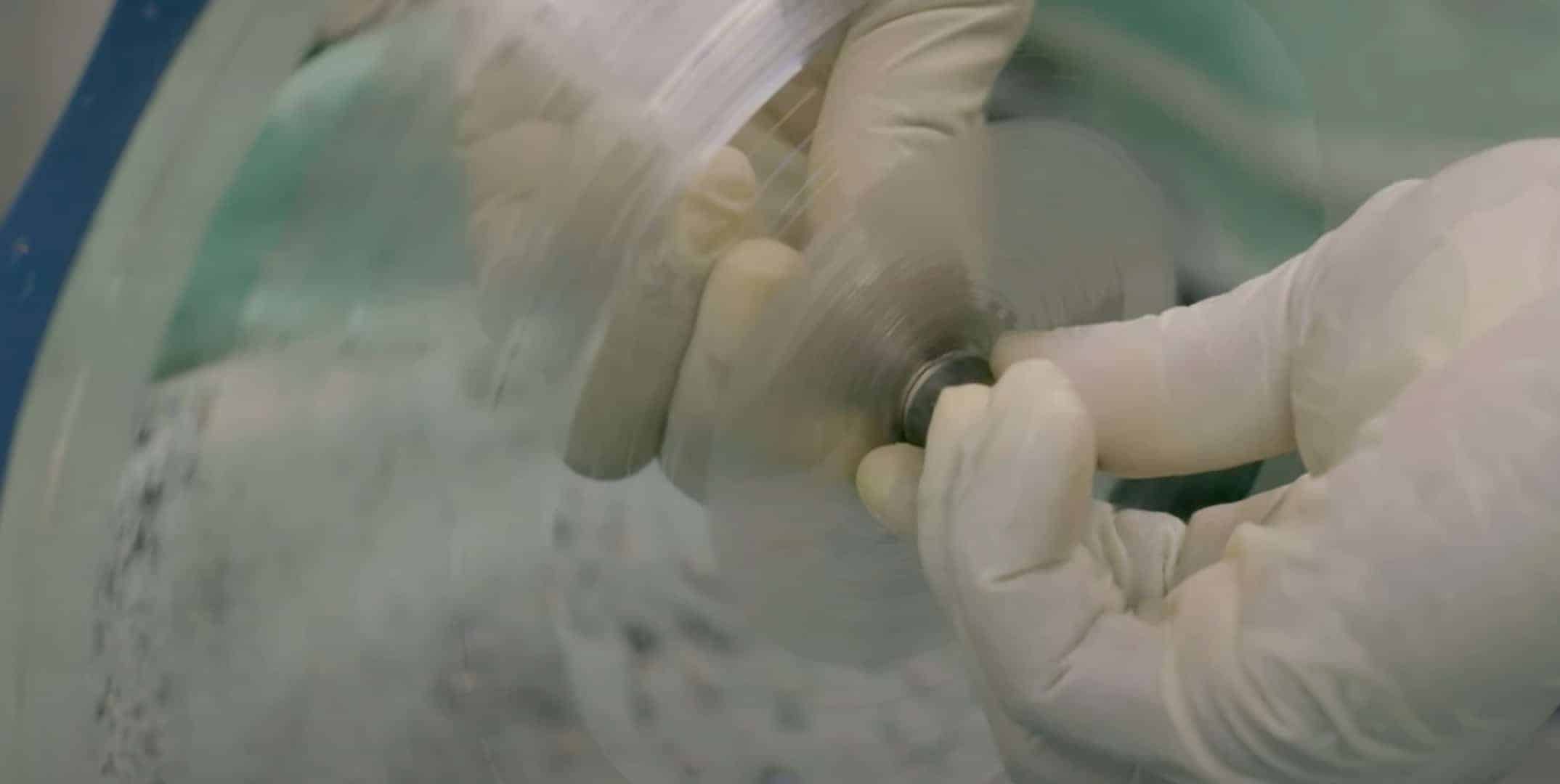

The process of electroplating in vinyl records is much the same as electroplating anything else. The lacquer is cleaned then dried and after drying they move on to be sprayed with a silver spray. The silver spray is used to create a negative of the lacquer.

This silver negative is then placed into an electrically charged liquid metal bath where nickel binds to the album. After the plating is complete they peel the “Father” from the lacquer and use it to produce the stampers or “Mothers”.

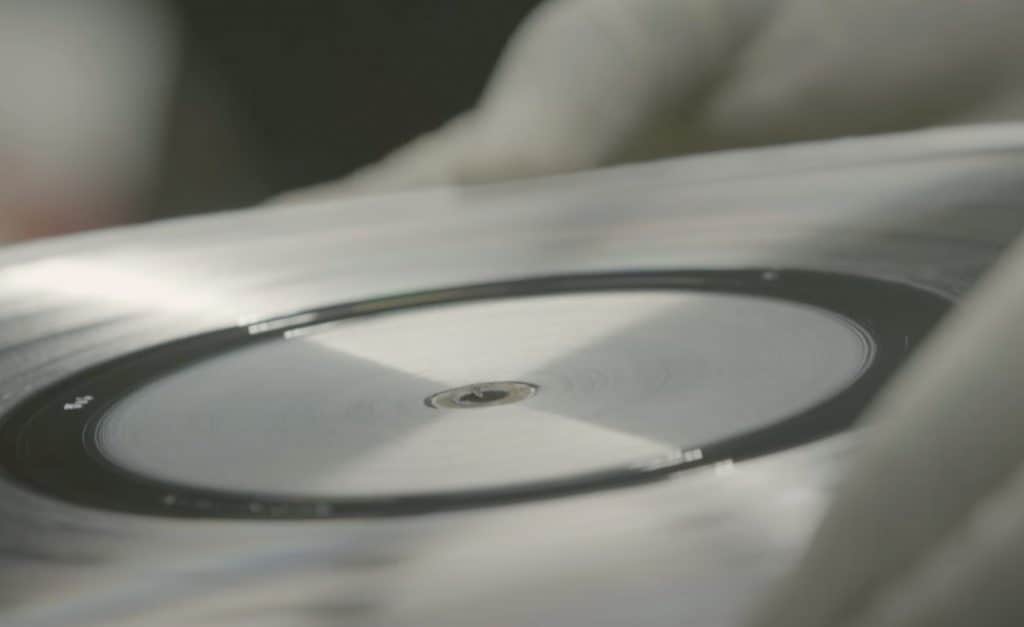

Cleaning Up The Template

After all the plating is done the final part of producing the metal master is cleaning the album up and preparing it to become a mold. The templates are inspected and trimmed to size as well as recentered. Albums lose their centering during the plating process so they use the exit groove to find the center and punch a center hole in the template.

The template once cleaned up, centered, and trimmed is moved to a machine to have a profile pressed. The profile is precisely pressed so that the template can be added to the actual press.

Templates Off To The Press

A template or “Mother” for a record can be used to produce around 1000 copies any amount over this runs the risk of having bad pressings and poor audio quality. All the work before this is just to create a press. This is all necessary even if we are pressing just 1 record!

At this point, the templates are inspected then attached to the press so production can get started. The manufacturer will attach a template to a clamping system that goes around the template and a center spindle.

Step 4: Pellet Biscuit Creation

Before a record can become a record it lives its life as a synthetic plastic pellets. These little pellets look similar to rabbit food or lentils. They come in all kinds of colors which can make vinyl records have all kinds of designs and shades of colors.

Pellet Materials

So you may be asking yourself “Ok they are made of plastic pellets but what are the pellets made of?” Ok, maybe you are not as nerdy as we are and do not actually want to know what they are made of. Out of full-on Vinyl Bro nerdiness, we are still going to break it down for you.

Plastic pellets used for producing vinyl records are made from Polyvinyl Chloride. Which is produced crude oil and chlorine. This type of plastic actually helped start the plastic boom but that is a whole other subject. If Polyvinyl Chloride sounds familiar that is because it is the same thing some plumbing pipes are made of called PVC pipes!

Color Selection

Poly vinyl chloride Pellets of any color can be mixed in various ways to create a lot of cool effects. In Vinyl Bro’s collection, we have just about any color vinyl you could want. We have some that are clear with a smoke effect, one is Rastafarian color-themed, others are pink, some orange, or even just standard black.

Biscuit Extrusion

Once the vinyl records color scheme is picked the plastic pellets are moved to an extruder. This extruder’s job is to heat the pellets and form what is called a biscuit or cake. It is a round think puck of hot vinyl that is weighed to a precise amount. This biscuit will become the record you listen to at home once pressed into shape and trimmed.

Step 5: Pressing Your Vinyl Record – The Stamper

The pressing process is when the record is actually produced. In this stage the record actually become visually completed and physically completed. At the end of this stage you will be able to listen to the records.

Center Labels

Labels start off square-shaped but are then punched out into circles with a hydraulic press. The labels are then baked in an oven to remove all moisture so bubbling does not occur. These labels are placed in the center of the press then the biscuit and the other label follows.

The labels that are placed here are the center labels you are used to seeing on your vinyl records. The label is actually pressed into the record during the next step. This means the labels do not require any adhesive or glue to stick.

Pressing The Biscuit

Once the biscuit has the labels the press starts the next process of pressing the biscuit into the actual vinyl record. 300 degrees Fahrenheit (148 °C) of steam is applied to further soften the vinyl. The hydraulic press then applies around 100 tons of pressure and 345 degrees Fahrenheit to the biscuit in order to create a record.

After the press completes its timed cycle the record has all the grooves copied exactly onto the new vinyl. The press cools before opening allowing it to be removed and moved on to the trimming process. The cool part here is that the vinyl could technically be played! The trimming removes the excess vinyl around the edges to cut it to the desired size: 7 inches, 10 inches, or 12 inches.

Trimming Edges

After the record has been pressed there is always a bit of excess left around the edge of the record. This extra material is trimmed by a mechanical trimmer. This is to remove the ugly ends and cut them to the correct size: 7 inches, 10 inches, or 12 inches. Manufactures usually keep the trimmings and recycle them back into biscuits for the next records.

This is the final stage of production which means now the records are completed and ready to be moved to the quality control phase of its life.

Test Pressings

Prior to fully starting production on a record the press will run around 10 test pressings. These test pressings are to detect minor defects that can become bigger problems when put on vinyl. For instance surface noise that does not exist on other formats. These test pressings are usually sent to the record label or the artist to listen to for final approvals.

Inspecting Your Vinyl Record

There are two stages of inspection done on records. One happens on the assembly line and the other is done in the studio. These are both important to ensure that you end up with a perfect end product.

Line Inspection

The line inspection is the first step of the inspection process. This is where someone physically looks at the record to see if there are any visible imperfections. This step happens after a stack is completely done with the pressing process. If there are no visual defects in the vinyl records they move on to packaging where they will be placed in inner sleeves and outer jackets.

Quality Control Inspection

There is usually a position at every manufacturer whose job is to listen to randomly selected records from the press batches for imperfections. This is a job where someone gets paid to listen to vinyl records all day! This job is a very important part of the production process as this is the last line of defense for the manufacturer to find any issues caused during the process.

This is a very time involved task that most manufacturers are committed to completing. The main reason for this step is visually a record may pass inspection but 10% – 20% do not make the final audio cut. The records that do not make the cut go right back to the pellet machine to become another record.

The person usually selected to do this job is a highly-skilled technician that knows what to look for and listen for. The process is literally as simple as, randomly selecting a record in the batch, visually inspecting it, then listening to the record, and if there are any problems they note the lot of the pressings and recycle the batch.

Packaging The Vinyl Record

Some manufacturers offer printing in-house and others do not. Either way, the artist will choose the artwork, inner sleeves, outer jacket artwork, and style for their records to be packaged in. We personally love it when artists choose gatefolds because even if it is only one LP it gives us more artwork!

Even if the manufacturer does not offer printing services in-house they are usually the ones to package the final product. Once the packaging is completely assembled they will then shrink wrap the albums. Now they are ready for shipping to distributors and fans.

How Are Records Made?

The whole process of records being made is really fascinating. This is a time-honored process that has aged really well without many changes in the last 50 years. This format of music has been held in many people’s hearts as the best for a long time. We for one hope to see it continue to grow!

To better visualize how records are made here is a really great video that shows the process United Record Pressing in Nashville, TN uses.

It is really awesome to see this process in action. United Record Pressings has been pressing vinyl since 1949 and shows no signs of slowing down. Their production is so strong that they just moved to a larger facility in order to keep up. A really cool thing that we like about United Record Pressing is that they offer tours of their facility where you can see vinyl records being made!

We hope you enjoyed our write-up on how records are made and look forward to writing more in-depth information, the Vinyl Bro way, to keep you reading!

Frequently Asked Questions – How Are Vinyl Records Made? How A Vinyl Record Is Made

How are vinyl records made?

Vinyl records are made through a process called vinyl record manufacturing. This involves cutting grooves into a lacquer disc, creating a master recording, and then using this to press new vinyl records.

What is the cutting process for vinyl records?

The cutting process involves using a stylus to cut grooves into a lacquer disc. This is done with the original recorded music and is used to create the master recording for pressing vinyl records.

What is the purpose of a stamper in vinyl record production?

A stamper is used to press vinyl records. It is a key component in the production process, as it is used to create mirror image copies of the original master recording.

What is the role of the nickel bath in vinyl record manufacturing?

After the lacquer disc is sprayed with silver and then dissolved in nickel, the resulting nickel disc is used to create the stamper for pressing the vinyl records.

What is direct metal mastering in the context of vinyl records?

Direct metal mastering is a specific technique used to cut grooves into the lacquer disc. This method is known for creating a higher dynamic range than digital recording, enhancing the quality of the sound waves.

What are biscuit and labels in the production of vinyl records?

Biscuit refers to the raw vinyl discs before they are pressed, while labels are the identifying marks added to the vinyl records after they are pressed, often including the serial number.

How can excess metal be removed from vinyl records during production?

Excess metal is typically removed using a hopper, ensuring that the final vinyl records have a smooth surface with properly defined grooves to avoid distortion.

How are test pressings used in the production of vinyl records?

Test pressings are used to assess the quality of the sound and overall pressing of the vinyl records before mass production. This ensures that any issues can be identified and corrected beforehand.

What equipment is used for playing vinyl records?

Vinyl records are played using a turntable or record player equipped with a needle, typically made of sapphire, to navigate the grooves and produce the recorded music.

How do vinyl records compare to digital recordings in terms of sound quality?

Vinyl records are prized for their warm analog sound and higher dynamic range compared to digital recordings. This is due to the physical nature of the grooves and the audio being directly translated by the needle and played through a traditional analog system.